When the idea of manufacturing a car is brought up, the first thing that creeps to mind is the assembly line churning out cars nonstop, but there is another world of building automobiles. Its the low volume sector. Cars are assembled one by one in a less frantic pace. Mainly sports cars are built this way especially the British small sports car industry. The assemblies draw a lot from skilled metallurgy and keen craftsmanship to produce cars in a way intricate manner.

What does this have to do with Naijacar and synergies? A whole lot. Nigeria has many skilled metal, wood, and textile craftsmen. There is also a handful of mechanics with strong knowledge on workings and repair of older cars. Then there's the hustling and bustling parts industry in eastern Nigeria especially Nnewi, Anambra. One can just imagine all these sectors coming together and producing a vehicle out of the synergies of all the different diverse skill sets. working in a low volume volume outlet would avoid the huge overhead costs necessary for full scale mass production while making effective use of the readily available skills of the craftsmen and mechanics.

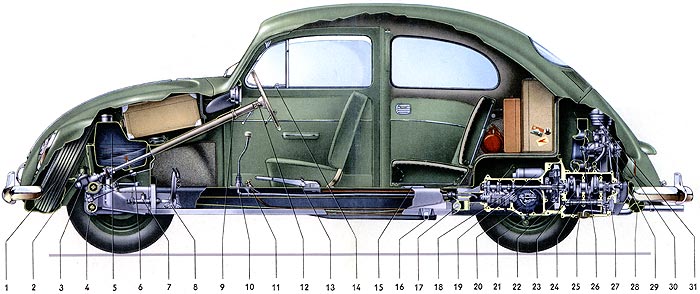

The essential components like engine and gearbox could be sourced from a current established manufacturer and the engineering could be done in Nigeria and the components produced by different parts manufacturers with all the pieces coming together in the hand s of the metal, wood and textile fabricators under the supervision of the engineers of the car. The Sri-lankan micro-car started and is still made this way. with production doubling gradually every year. The gradual process will nurture the components industry to the high standing degree necessary to sustain a local car manufacturing industry.

As the industry matures, engine production could be moved locally taking further advantage of the inexpensive labor cost. Such baby steps could see a Nigerian car surface relying on the gutsiness of the Nigerian entrepreneurs and without the over promising underachieving efforts we have come to know from the Nigerian government. The set-up could also be more flexible under the patchy power supply. Mass production assembly lines require constant uninterrupted supply of electricity which is a far cry in Nigeria. Its about making the best use of what we have and as the market grows it will force the other things like constant electricity to follow.